Tile Panel Backside Fixing:

Tile panel backside fixing in two options:

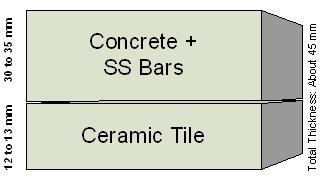

Option 1: Sand and cement as concrete plus stainless steel bars for backside fixing of our ceramic tile panels for all ceramic tile options. In this case the total thickness for our ceramic tile panels will be 45 mm.

After putting concrete at the backside of our ceramic tile panels, it takes about 2 to 3 days (depends on the climate) to be dried and ready for the installation on its place. Then we lift the panel and install it at its place. We fill the same concrete in the space between the wall and ceramic tile panel.

This option is for Moarragh, Gereh, Moarragh 3D and Moagheli ceramic tiles. We do not use this option for Especial Seven Color / Polychromic ceramic tiles.

For Especial Seven Color / Polychromic ceramic tiles, we put each tile one by one on its place beside each other and after completing its row, we fill concrete in the spaces between the wall and polychromic tile (Normal Installation). We normally do not use any SS bars at its back.

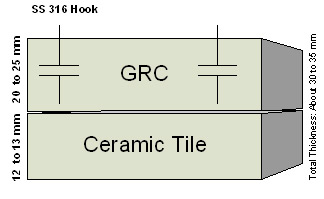

Option 2: Using GRC (Glass Reinforced Concrete) for backside fixing of our ceramic tile panels. The GRC we use is normally mixture of special cement, silica sand, alkali resistant (AR) glass fibers and water that can be sprayed directly onto the backside of our ceramic tile panels. Before that we put some SS 316 Hooks (at the backside of our ceramic tile panels inside GRC) as mechanical fixing which will be secured / bonded to the substrate (depends on the place of installation and the weight of our panels, we normally use 4 to 5 numbers of SS 316 hooks in each sq meter). In this case the total thickness for our ceramic tile panels will be about 35 mm.

After ceramic tile panel get ready, we lift the panel and secure its SS hook to the hook placed on the substrate. We fill the space between the wall and ceramic tile panel with cementation mortar.

This option is for Moarragh, Gereh, Moarragh 3D , Mogharnas and Moagheli ceramic tiles.

We do not use this option for Especial Seven Color / Polychromic ceramic tiles.

|

![]()

![]()